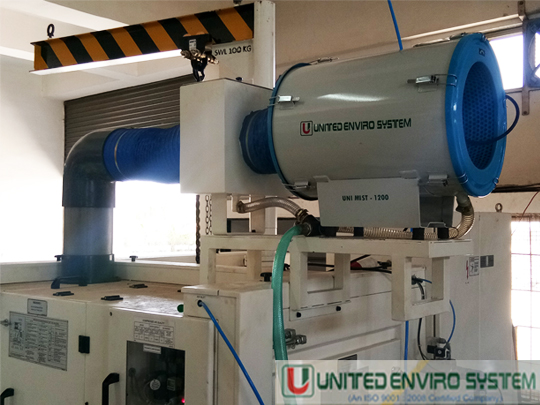

We are Manufacturers, Suppliers, Exporters of Mist Collectors, Oil Mist Collector for CNC Machines, Centrifugal Oil Mist Collectors, Small Mist Colllectors and our set up is situated in Pune, Maharashtra, India. Mist along with dust laden air is drawn in to unit by high speed rotating rotor. Small particles are forced to collide and coalesce due to centrifugal force of rotor resulting in to formation of liquid droplets. Thus formed liquid is drained back to the machine tool with pressurised draining system. Dust accumulates on the surface of filters which is placed next to rotor, this unique arrangement reduces dust load on the rotor there by reduces the vibration and related problems. Uni mist unit works on basic principle of static filtration. Filters having more surface area are provided to increase the cleaning frequency of filters. These units offers 97.1% filtration efficiency can be extended up to 99% efficiency with clip on high efficiency particulate arrestor (HEPA) filters.Most Suitable for : The machining applications having mist along with high dust load concentration like grinding, CI machining etc.

These units works on basic principle of centrifugal impaction. Perforated drum driven by electric motor rotates at high speed which sucks oil mist and dust in to the unit. Mist gets impacted by specially designed vanes of perforated drum at high velocity, small particles are forced to collide & coalesce there by suspended liquid droplets gets separated and thrown against inner surface of outer casing by centrifugal force. Thus separated liquid is recycled through pressurised draning system. These units offer 98% filtration efficiency, can be extended up to 99% efficiency with clip on high efficiency particulate arrestor (HEPA) filter. Most Suitable for:The machining applications having mist along with low concentration of dust like turning, hobbing, honing, tool grinding, thread grinding etc.

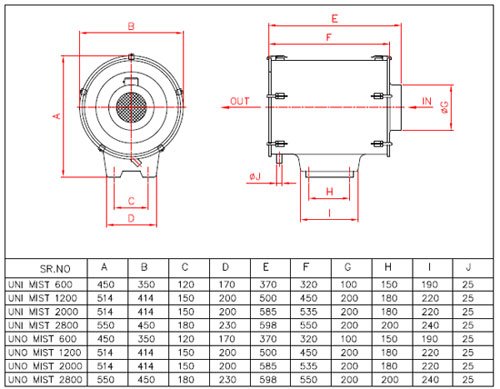

| Particulars / Model | Uni Mist | Uno Mist | |||

| 600 | 1200 | 2000 | 2800 | |

| Motor – Power (H.P.) 3Ph, 415V / 220V (Optional) |

0.5 | 1.5 | 1.5 | 2 |

| frequency Hz | 50Hz / 60Hz (Optional) | 50Hz / 60Hz (Optional) | 50Hz / 60Hz (Optional) | 50Hz / 60Hz (Optional) |

| R.P.M. | 2880 | 2880 | 2880 | 2880 |

| Air Flow M3/hr. CMH | 600 | 1200 | 2000 | 2800 |

| Operating noise dBA | 63 | 65 | 65 | 68 |

| Inlet dia. mm | 100 | 200 | 200 | 200 |

| Drain pipe dia. mm | 25 | 25 | 25 | 25 |

| Thermal Degree Cen. | 60 | 60 | 60 | 60 |

| Weight Kg’s | 21 | 34 | 42 | 45 |

| Construction / Std. Colour | Mild steel / Main body RAL 7035, Side covers Deep blue powder coated | |||

| Unit Mounting | Horizontal / Vertical | |||

-

Compare these Facts :

Power advantage : All units are designed to operate at low motor power for high air valume and filtration efficiency. Please refer technical chart for you ready reference.

Low cost : The most cost effective equipment available and offers good value for money. Its is 100% indigenous

Versatile : Uni Mist / Uno Mist series made of modular components ensuring the highest flexiblility, once installed Uni Mist / Uno Mist can be adapted to alter or extend the type of application with out much effort.

Easy Maintenance : Cleaning or replacement of filters can be performed simply by de clamping toggle clips and removing front & back covers which are light in weight. Fiters come along with covers.

Service : It is important to UES that our customers consider us their partner. For this reason, we strive not only to sell a product but to provide our customers with comprehensive service as well. We assure time guaranteed service support to you.

- Rotor and perforated drum are dynamically balanced

- Pressurised liquid draning

- Standard shaft motors, no special motors required

- Low motor power for high air volume

- Motor compatible with other voltages

- Compact size

- Stainless steel units for special applications

- Customer specified main body coating colours

Salient Features of our mist collection systems :

Application :

High air volume oil mist collectors ranging from 1000 CMH to 8000 CMH for open type machines, centralized unit for group of machines

Mechanism :

Oil Mist and dust laden air is drawn down the spiral tube. Oil mist is propelled by centrifugal force to the outer tube wall separating larger oil droplets which falls down to the tank. air is drawn up through the inner tube of spiral and passes through demister and HEPA filter to separate finer particulates.

Features :

Superior collection efficiency :

Combination of spiral tube filtration chamber and high performance filters to separate and collect liquid.